Parameter:

Description | Parameter |

X,Y,Z working area | 2000*3000*200mm |

X,Y Structure | Rack and pinion; Taiwan HIWIN guide rail 20mm |

Z Structure | Ball screw 2510; Taiwan HINWIN guide rail 20mm |

Motor | Stepper system 450B |

Drive | Leadshine MA860H |

Inverter | Fuling 5.5kw |

Spindle | Air-cooling |

Spindle power | 4.5kw |

Spindle speed | 0-18000RPM |

Lathe bed frame | Steel square tubes |

Table surface | Vacuum table |

Fixing method | By clamps |

X,Y,Z repositioning accuracy | ±0.03mm |

X,Y,Z traveling accuracy | ±0.03/300mm |

Max working speed | 20000mm/min |

Max rapid travel speed | 30000mm/min |

Working voltage | 220/380V/50/60Hz |

Operating system | DSP system |

Command language | G code |

Computer interface | USB |

Flash memory | 128M(U Disk) |

Collet | ER20 |

Resolution | less than 0.02mm |

Software compatibility | Type3/Artcam/Artcut/Ucancam/JDpaint etc |

Running environment | 0~45 centigrade |

Relative humidity | 30%~75% |

Product Features:

1.Square Tube lathe bed with more solid structure and strong stability because of low center of gravity.Whole machine is welded with seamless steel structure, the rigidity is good , not easy to be

deformed.The side board of gantry adopt steel structure.

2.High precision Germany linear square tracks, with ball sliders in two arrays and four rows, makes large load bearing and stable running.

3.High power spindle with good rigidity not only demonstrates superior performance in woodworking application, is also propitious to engrave and cut on copper, aluminum, iron and other metals.

4. With imported rack and gear transport system, largely improve the speed of the machine .

5. Imported linear square rails, dual four slider, loading capacity, smooth operation and high precision, long life, under the knife precision.

6. Software compatibility, and compatible with Typ3/Artcam/Castmate / Wentai, and other CAD / CAM design software

Advantages:

1 .Welded structure by thick profiled steel stabilized under high temperature, ensures minimum distortion, excellent rigidity and powerful strength.

2. Japanese YAKSAWA servo motor makes the machine stable running with low noise, high speed and high accuracy.

3. Italy HSD spindle makes machine with high precision, long service time and stable movement.

4. Configured with carousel tool magazine of 12 tools, the machine can change tools speedy and freely.

5. Auto tool sensor enables the machine compensate the tolerance of the tool length.

6. High power suction vacuum pump, air-cooling, water-cooling or becker pump.

7. Taiwan SYNTEC control system, separated keyboard control, color LCD display, can alter the parameters and automatically change the tool .

8. Strong dust collector ensures site cleanliness during the machine operation.

9. Automatic lubricating system, one touch can finish periodic maintenance easily.

Application:

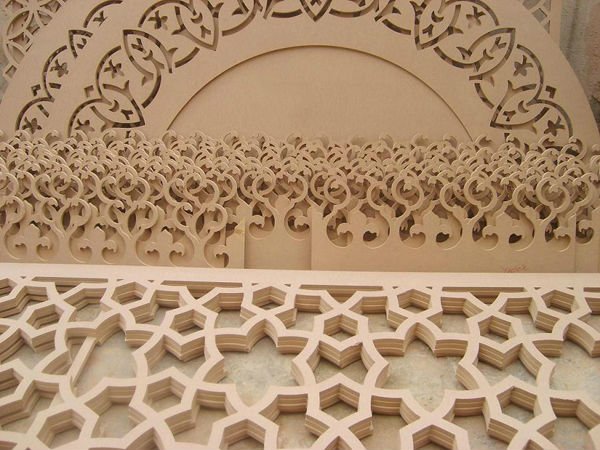

1. Furnitures: kitchen cabinets, closets, entertainment centers, mdf doors.

2. Woodworking: voice box, game cabinets, computer tables, sewing machines table, instruments.

3. Panel Processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

4. Decorations: acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum.